Historical Context and Evolution

The journey of webbing in automotive design began with its early use for seat restraints and simple securing purposes. Initially, webbing was rudimentary but functional, providing basic support and reliability. As automotive engineering advanced, so did the need for specialized types of webbing designed to meet stringent safety standards and specific functionalities. This evolution led to the introduction of color-coded webbing, such as three white and two black webbing, each serving a distinct role within vehicle systems.

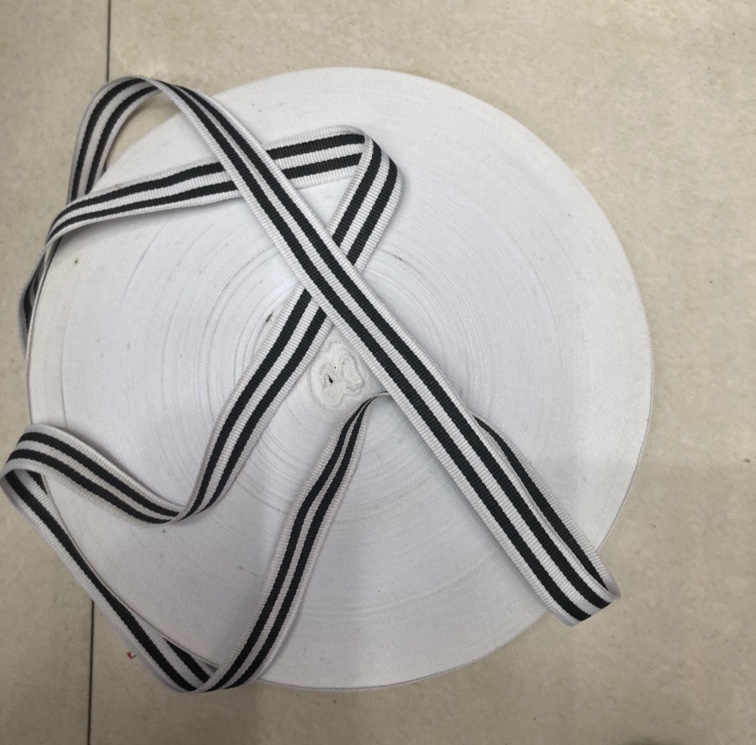

Material Properties and Specifications

The composition and durability of webbing materials are critical factors that define their application in the automotive sector. White webbing typically offers high visibility and strength, making it ideal for safety-critical applications. Meanwhile, black webbing often provides a balance between reinforcement and subtle aesthetics.

Three white webbing is recognized for its superior tensile strength and conspicuousness, whereas two black webbing excels in providing additional reinforcement without compromising discreet design. Both types adhere strictly to automotive standards and certifications ensuring they are fit for vehicular use.

Safety Implementations

In the realm of safety, webbing plays an indispensable role in manufacturing seatbelts which are vital for passenger protection. The three white webbing is preferred due to its high breaking point and prominent visual feedback, aiding quick inspections and replacements. On the other hand, two black webbing integrates seamlessly into interior designs while still offering robust support essential for secondary restraint mechanisms like airbags.

Webbing used in both primary and supplementary restraint systems undergoes rigorous testing for quality assurance and compliance with international safety regulations, ensuring reliability in real-world scenarios.

Aesthetic Enhancements

Aesthetic appeal is another domain where three white and two black webbing shine. In luxury and sports vehicles, the contrast stitching provided by these webbings adds a refined touch, enhancing the overall interior look. Car manufacturers offer customization options allowing customers to select webbing that matches or contrasts with upholstery and trim. This bespoke approach aligns with current automobile trends emphasizing personalization alongside performance.

Practical Applications in Car Repairs

Beyond manufacture, webbing proves valuable in car repairs, specifically in replacing or repairing seatbelts. Mechanics can match original specifications using identical three white or two black webbing, ensuring repaired components meet established safety criteria. Moreover, these webbings find utility in securing loose parts or cargo, functioning as a quick-fix method for temporary solutions during travel or transport.

Cost Efficiency and Longevity

Economically, durable webbing significantly reduces long-term costs associated with frequent replacements. High-quality webbing like that from Yiwu City Chutian Ribbon guarantees prolonged performance, thus cutting expenses over time. Case studies confirm that when comparing alternative materials, the initial investment in premium webbing pays off through minimized maintenance and extended lifespan.

Environmental Considerations

Eco-conscious practices have seeped into webbing production, promoting sustainable manufacturing processes that reduce environmental footprints. Additionally, innovations aim at improving recyclability and minimizing disposal issues related to worn-out webbings. Future developments are likely to focus further on creating eco-friendly materials without sacrificing strength or functionality.

Future Trends and Innovations

Looking ahead, advancements in webbing technology promise exciting potentials. Smart webbing integrated with sensors could provide real-time data on wear and tear, enhancing preventive maintenance strategies. Moreover, autonomous vehicles might leverage this enhanced webbing for improved safety features and innovative cabin functionalities.

Expert Opinions and Industry Insights

Automotive engineers and designers consistently highlight the crucial role webbing plays in modern car design. Testimonials from manufacturers underline the importance of reliable webbing materials, echoing predictions that smart and adaptable solutions will shape the industry’s future.

DIY Tips and Best Practices

For DIY enthusiasts venturing into car projects involving webbing, selecting the right type based on application needs is paramount. Adhering to safety tips ensures not only successful fixes but also personal protection during tasks. Regular maintenance prolongs the life of automotive webbing, safeguarding ongoing efficacy and appearance.

Real-World Examples

Successful incorporation of three white and two black webbing by leading carmakers sets benchmarks for others in the industry. Notable models showcasing these materials affirm user satisfaction and safety adherence. Feedback from owners corroborates the benefits described, highlighting practical advantages experienced firsthand.

Resources and Further Reading

To dive deeper into the world of automotive webbing, numerous authoritative books and articles offer extensive insights. Online forums serve as vibrant communities for sharing advice, experiences, and recommendations. Engaging directly with suppliers specializing in automotive webbing, like those from Yiwu City Chutian Ribbon, enables sourcing top-tier materials tailored for industry-specific demands.