The Versatility of White Webbing in Industrial Applications

Safety Harnesses and Fall Protection: In high-risk environments such as construction sites and elevated workspaces, ensuring worker safety is paramount. White webbing is commonly used in safety harnesses due to its exceptional strength and durability. The robust material can withstand significant weight loads and harsh conditions, which are critical factors in preventing falls and enhancing overall workplace safety.

Load Securing in Transportation: Transportation industries rely heavily on white webbing for securely fastening cargo in trucks and freight systems. This application complies with stringent safety standards and regulations, mitigating risks associated with the shifting or falling of goods during transit. High-quality webbing ensures that transported items reach their destination intact, maintaining logistical efficiency.

Medical and Healthcare Equipment: In the healthcare sector, white webbing finds crucial applications in stretchers and patient transfer systems. Its ease of sterilization and hygienic properties make it suitable for medical use where cleanliness is a priority. The flexibility and resilience of the material contribute to safe and efficient patient handling and movement within healthcare facilities.

Distinctive Roles of Black Webbing

Military and Tactical Gear: Black webbing plays an essential role in military and tactical gears like backpacks, belts, and vests. Due to its camouflage abilities and non-reflective qualities, black webbing helps personnel remain undetected in various operational settings. The sturdy construction supports heavy-duty use while providing functionality and reliability under strenuous conditions.

Heavy Machinery and Equipment Straps: Durability is key when dealing with heavy machinery and equipment. Black webbing offers remarkable resistance to abrasion and wear, making it ideal for straps used in these demanding environments. Equiments secured with black webbing tend to have extended lifespans thanks to the material's capability to endure extreme conditions without compromising integrity.

Combined Uses for Enhanced Efficiency

Hybrid Safety Solutions: Combining white and black webbing in multi-functional safety gear yields hybrid solutions that leverage the strengths of both materials. For instance, certain case studies highlight how mixed webbing enhances visibility and performance in safety kits tailored for diverse tasks and conditions. These mixtures optimize protection measures, thereby safeguarding users more effectively.

Securing Large Equipment and Machinery: Using white and black webbing together provides several benefits when securing large equipment and machinery, especially regarding visible contrast and added strength. Techniques involving dual-colored webbing offer increased safety by delineating different sections or stress points, ensuring precise and reinforced binding that minimizes potential hazards.

Innovations and Future Trends

Technological Advancements: Ongoing innovations in webbing technology bring forth new materials and coatings that significantly enhance performance capabilities. Developments include smart webbing embedded with sensors to monitor real-time stress and tension, contributing to advanced safety protocols and maintenance strategies across multiple industries.

Sustainability and Recycling: As environmental concerns rise, eco-friendly production methods become increasingly pivotal in the manufacturing of industrial webbing. Focused initiatives on lifecycle management and recyclability not only reduce waste but also promote sustainable use of resources. These efforts pave the way for greener industry practices and consumer consciousness.

Real-world Case Studies

Construction and Infrastructure Projects: Numerous examples exist showcasing the effective utilization of webbing in large-scale projects. From skyscraper constructions to extensive infrastructure developments, feedback from industry professionals consistently underscores the reliability and necessity of quality webbing products like those offered by Yiwu City Chutian Ribbon.

Emergency Response and Disaster Management: Rapid deployment and unwavering reliability are imperative during emergencies. Success stories from disaster management scenarios demonstrate how dependable webbing facilitates quick response actions, aiding in rescue operations and emergency logistics. Lessons learned emphasize the life-saving potential inherent in high-grade webbing applications.

Best Practices and Safety Standards

Regular Inspection and Maintenance: Ensuring the integrity of webbing through regular inspection and maintenance is crucial. Adhering to guidelines for routine checks helps identify common issues such as fraying or weakening spots early on. Addressing these problems promptly prolongs the lifespan of the webbing and maintains optimal safety levels.

Compliance with Industry Standards: Understanding and aligning with relevant regulations and certifications cannot be overstated. Compliance with recognized safety protocols guarantees that webbing products meet essential criteria for performance and security, fostering trust among users and stakeholders alike.

Conclusion

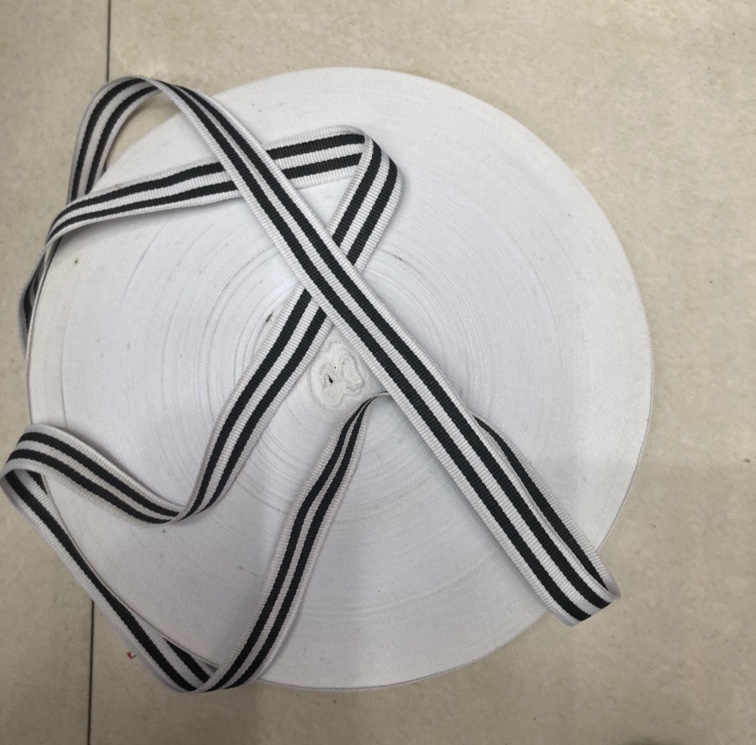

In summary, the diverse applications and numerous benefits of integrating white and black webbing in industrial settings confirm its indispensable role. Products like the premium Three White and Two Black webbing from Yiwu City Chutian Ribbon exemplify cutting-edge solutions catering to rigorous demands across various sectors. With ongoing advancements and heightened focus on sustainability, the future of industrial webbing promises continued innovation and wider adaptation.